About HercuWall®

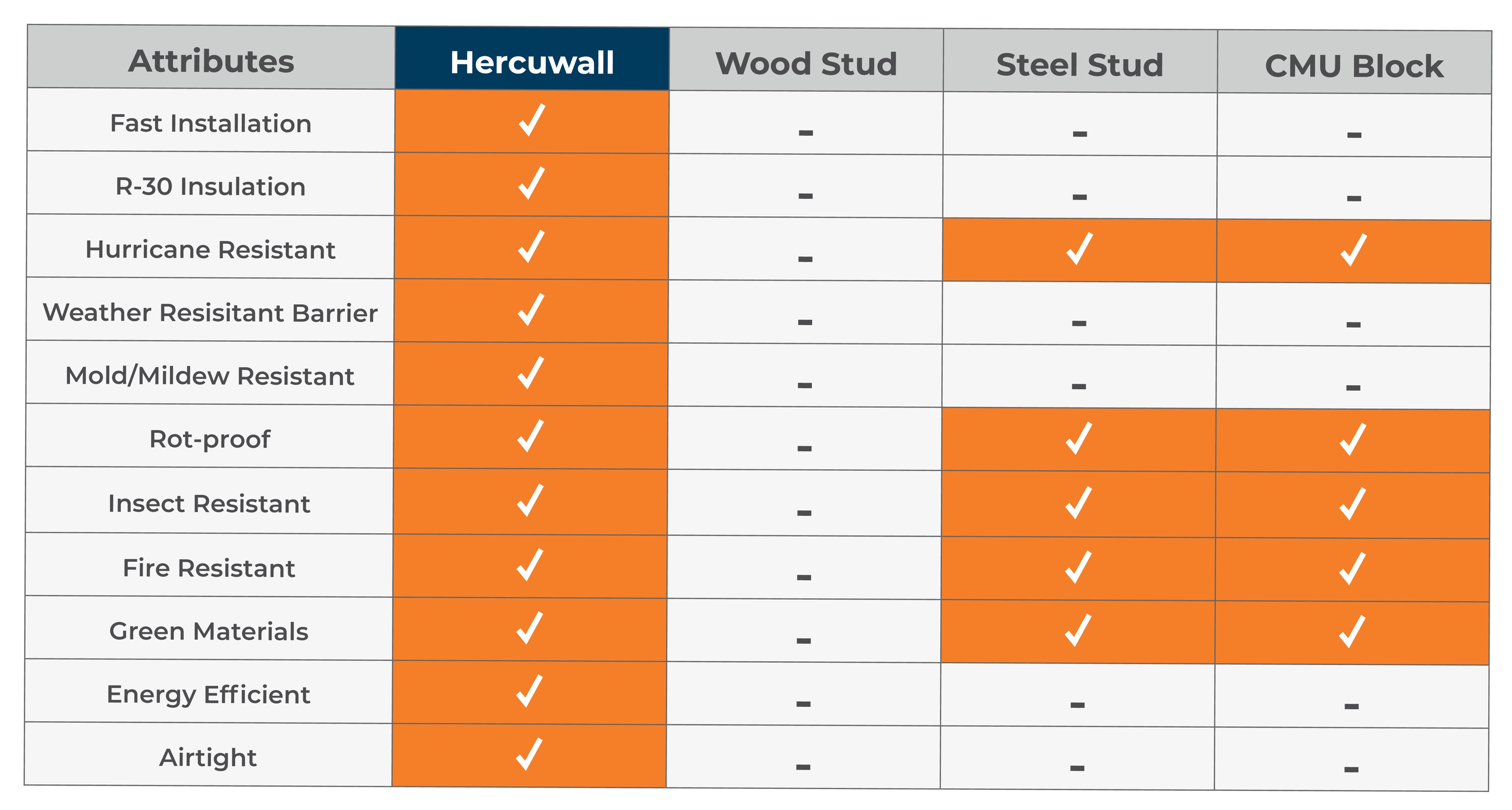

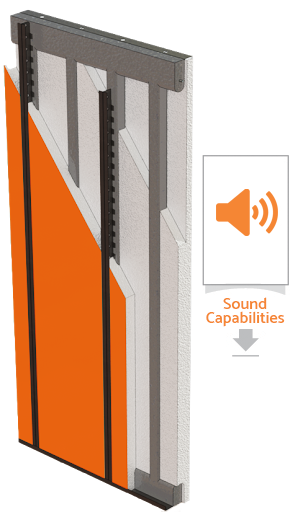

Gain the competitive edge with the panelized shell and demising wall system that eliminates costly and time-consuming steps, and radically raises energy efficiency. Flex your confidence while delivering superior strength, sustainability, fire resistance, sound rating and overall building quality.

This ICC certified modular construction solution far surpasses typical construction. Made of concrete, steel and EPS, everything about HercuWall’s power is in its unique, patented structure. This delivers R31 insulation and is three times stronger than 2 x 4 wood stud. All while being light enough for one man to carry.

* ASTM E119 NFPA 285 & 286

** High Velocity Hurricane Zone (HVHZ) rated Miami Dade Compliant

Gain the competitive edge with the panelized shell and demising wall system that eliminates costly and time-consuming steps, and radically raises energy efficiency. Flex your confidence while delivering superior strength, sustainability, fire resistance, sound rating and overall building quality.

This ICC certified modular construction solution far surpasses typical construction. Made of concrete, steel and EPS, everything about HercuWall’s power is in its unique, patented structure. This delivers R31 insulation and is three times stronger than 2 x 4 wood stud. All while being light enough for one man to carry.

* ASTM E119 NFPA 285 & 286

** High Velocity Hurricane Zone (HVHZ) rated Miami Dade Compliant

Process

Integrated Approach

With over ten years and capital invested in research and development, HercuWall created its digitized methodology, ALIGNEDASSEMBLY, to streamline design and installation and integrate seamlessly with your process. From design and drafting to manufacture, delivery and installation our AlignedAssembly process replaces the guesswork and rework of stick with planned precision, rapid, repeatable execution and simplified, safer handling. So it’s far easier to work with than ICF construction and other prefab wall systems.

Value engineering

We consult with your architects and engineers to optimize utilization of

HercuWall within their plans.

Digitization

Proprietary software converts your plans to HercuWall shop drawings —

used to manufacture precisely sized and cut panels.

Numbered

Each insulated wall panel is numbered for easy installation.

Project kit

Includes one-page build sheet with layout for each pre-numbered panel.

Delivery

Panels are delivered to the site in order ready for install.

Construction is changing. Yesterday’s approaches won’t put you ahead today. Smart builders are looking for better ways. The advantage is to pick the solution that works with your priorities. That’s why builders are teaming with HercuWall to build their shell and demising walls better.

HercuWall is focused on being recognized as a better way to build compared to stick and block. We’re committed to empowering our partners with resources and support to seamlessly integrate HercuWall into their process. Together, we achieve better results and build stronger relationships to tackle today’s construction challenges.

“We saved 2-3 months, while building a better product. HercuWall actually allowed us to increase both density and open spaces. So it’s better for our bottom line and makes us more competitive for tenants.”

Bruce Dunn

President

Paragon Development

“HercuWall gives us a better way to build better. The quality is much higher than stick and you don’t have to worry about labor, materials and all the rework. When you work smarter and safer, everything just goes more smoothly.”

Mike Mancini

SoDella Construction

“HercuWall is a differentiator that enables us to develop higher quality units with energy efficiency savings, which increases the desirability to our residents and brings value to all our stakeholders. It’s also integral to mitigating our risk through predictability in pricing, sourcing, quality and labor requirements.“

Scott Turkington

Paragon Development

“HercuWall is one of the highest-quality and energy efficient, panelized exterior and demising wall systems available for the construction industry. HercuWall’s professional collaboration team consisting of industry leading consultants, manufacturers, and suppliers ensure all efforts are made to deliver the most versatile, construction-friendly wall systems available today. ”

Architects and Engineers

Felten Group, Inc.

“Willis Engineering, Inc. has had the pleasure of assisting with the development and utilization of the HercuWall Concrete Panel System for structural designs on numerous home building projects. HercuWall is an innovative and versatile product that offers a unique opportunity to combine structural integrity with economic and energy efficiency. In addition, HercuTech provides excellent service in overseeing the fabrication, delivery, and installation of the HercuWall panels and facilitating the overall construction of a project.”

Architects and Engineers

Willis Engineering, Inc.